Engineering for a Sustainable Tomorrow

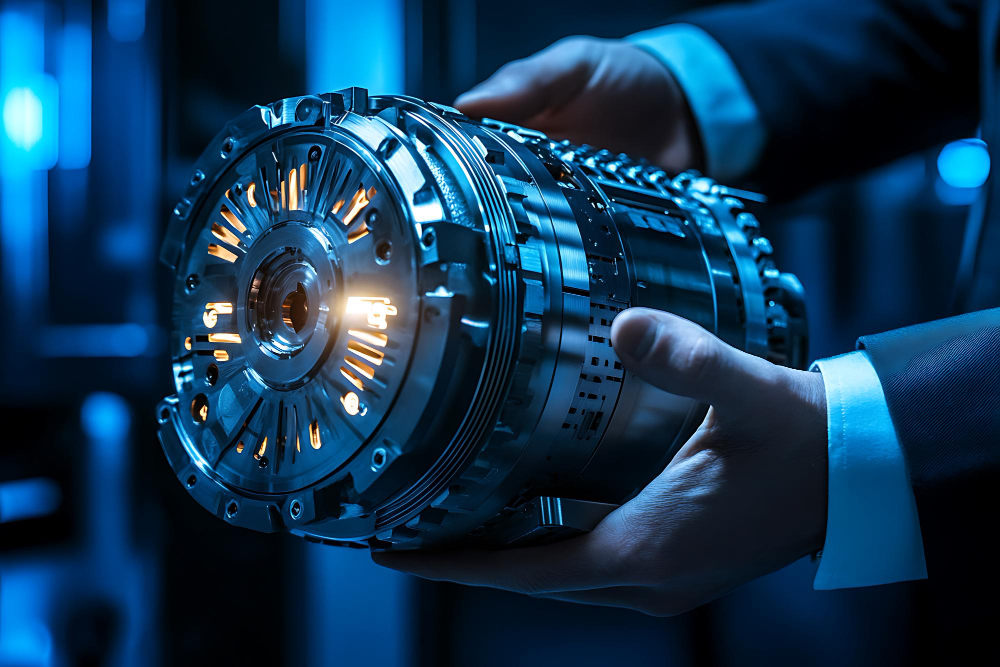

At Quill Industries, innovation drives everything we create. With world-patented gearbox technology, we are transforming the way industries consume and conserve energy. Our focus lies in engineering smarter power transmission systems that deliver superior performance while minimizing global energy waste. Through technology, precision, and purpose — we aim to shape a cleaner, more efficient industrial future.

Purpose

To engineer transformative gear transmission technologies that unlock the full potential of green energy systems, empowering industries to operate efficiently, sustainably, and at scale — especially in emerging and underserved markets.

Strategic Intent

To become the global leader in eco-efficient gear transmission systems that accelerate the adoption of renewable energy and decarbonization in emerging economies — through continuous innovation, strategic partnerships, and scalable manufacturing.

Mr. Bhavik Shukla, Founder & CEO of Quill

Our Vision

To create breakthrough technologies that accelerate humanity’s transition to a carbon-neutral, regenerative planet.

Read more

Our Mission

Our mission is to develop scalable, cutting-edge technologies that eliminate carbon emissions, restore ecosystems, and empower industries and communities to adopt regenerative practices—driven by innovation, collaboration, and measurable impact

Read moreIndustrial Solutions

Mechanical power transmission systems in heavy industry (e.g., cement, steel, mining, power, sugar) rely on planetary gearboxes to deliver high torque in compact footprints. Rising energy costs, decarbonization mandates, and uptime requirements make drivetrain efficiency a strategic priority. Even a 1–3% gain in gearbox efficiency can translate into large, recurring energy and CO₂ reductions.

Material Handling & Conveying Systems

Designed for long-distance and heavy-load conveyors, Quill’s drive systems ensure smooth acceleration, controlled torque, and minimal belt stress — even under high-inertia conditions.

- Controlled soft-start & synchronized multi-drive control

- Lower peak motor torque & reduced energy spikes

- Remote monitoring & easy retrofit

Mining & Bulk Material Industries

Engineered to endure harsh environments, our gearboxes provide unmatched durability and consistent performance in crushers, stackers, reclaimers, and conveyors.

- Heavy-duty casings and vibration-resistant clutch systems

- Simplified onsite servicing and remanufacturing support

- High torque density for large-inertia loads

Steel, Cement & Power Plants

Quill’s intelligent drives enhance productivity in high-torque, continuous-duty applications — improving uptime while lowering power losses and maintenance costs.

- High-efficiency gearing to reduce energy consumption

- Robust thermal & lubrication management systems

- Built for long run times with minimal maintenance intervals

Why Choose Quill?

With world-patented gearbox technology and a legacy of precision engineering, Quill Industries delivers intelligent power transmission solutions that redefine efficiency, reliability, and control across industries.

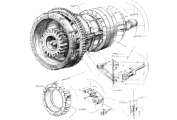

Engineering Process

Every project begins with understanding torque, speed, and operational efficiency goals. Our engineers conceptualize gearbox solutions tailored to specific industrial demands.

Using advanced 3D modeling and performance simulation, we refine the design to achieve maximum energy efficiency and durability before the first prototype is built.

With high-grade materials and precision machining, each gearbox is produced to meet stringent global standards for accuracy, performance, and reliability.

Every gearbox undergoes rigorous performance, load, and endurance testing — ensuring flawless function and long-term dependability before reaching our customers.

Driven by Innovation and Expertise

At Quill, our strength lies in our people — a team of visionary engineers, researchers, and industry leaders who combine decades of experience with a passion for redefining power transmission technology. From concept to creation, every gearbox is a reflection of our team’s precision, innovation, and commitment to global excellence.

Mr. Bhavik Shukla

Mr. Dharmesh Mistry

Mr. Niranjan Rajgor

Mr. Dipak Parmar

Across Industries